Professionists for passion

Our solutions can be defined by projects completely developed by our Technical Office, by Customer project, or can be the result of a co‐design. The construction phases are carried out according to internal Standards, in full uniformity with ISO‐9001 quality certification and modelled according to specific needs.

Design

Sistemi Quemme develops tailoring solutions in industrial automation, collaborating with professional employees in harmony and synchronization with Customers.

Elaborates ideas using 3D simulators such as EPLAN, SPAC AND BETACAD, according to the current Standards. Follows the customer towards a tailor‐made result to satisfy his unexpressed expectations.

Automation Cases

We are able to create different solutions in terms of Reference standards:

- European, UL / CSA, ATEX

- Control system: electromechanical solution, PLC, PC

- Field bus used for decentralization: Profibus, Canbus, Asi, others

- Dimensions and type of carpentry used: single, modular, special cabinets, control consoles

- Structure of the control system: centralized, decentralized Motion control solutions

Distribution Cases

We make electrical distribution boards. Our many years of experience in the field of electrical distribution panels and the skills developed in relation to the construction problems, allow us to deal with distribution systems with bars up to 3,000 A.

The solutions developed refer to the following market sectors:

- Industrial: electrical distribution boards for companies and supermarkets

- Civil: electrical distribution boards for hotels, hospitals, banks, museums, rest homes

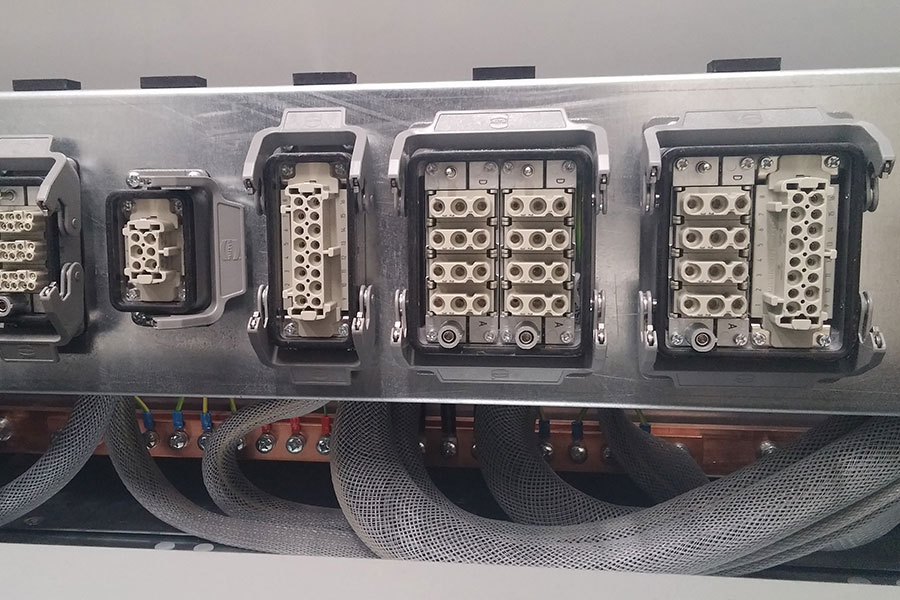

On‐Boards machine applications

The solution of connecting the machine edge to the electrical control panel by connection polyps is particularly effective in the case of:

- automatic machines with limited overall dimensions in terms of layout

- centralized or partially centralized control system structure

The solution consists in organizing the utilities on the machine by dividing them into a certain number of sheaths. In this way, the whole wiring part of the machine is prepared together with the relative control panel so as to deliver the panel with the connection cables to the utilities ready.

With our method we obtain a greater executive speed for the realization of the wiring on board and a significant reduction of the processing times normally required by the customer.

Electrical Systems

We are partners for the construction of systems, meaning installation and wiring activities related to:

- automatic machines with significant overall dimensions in terms of layout

- automatic lines

for which it’s therefore difficult to propose the solution of the “polyps” for the connection of the machine edge.

The professionalism and experience of our staff allow to ensure a result that meets customer expectations and is in line with the quality standards required by the market.